Design Better Workflows with Five Process Improvement Steps

Formalized process improvement steps and buzzwords can be difficult to translate into higher ed’s culture. Instead, follow five, jargon-free process improvement steps that every exercise should include. As your campus becomes more experienced in its process improvement journey, you may develop homegrown tools and resources—but these five steps should always remain your baseline.

Assemble the right people

First, create a process improvement team roster, ideally made up of 5 to 8 people who understand the process under consideration. Identify roles that should be represented on each process improvement team. This step may need project sponsor or senior leadership guidance, depending on the complexity of the process under review.

-

Research highlights

Successful process improvement projects begin with the right people. Tapping into different perspectives and approaches on a team is critical for understanding the entire “end to end” process improvement steps and then reengineering it to be more simple, standardized, and beneficial to the customer.

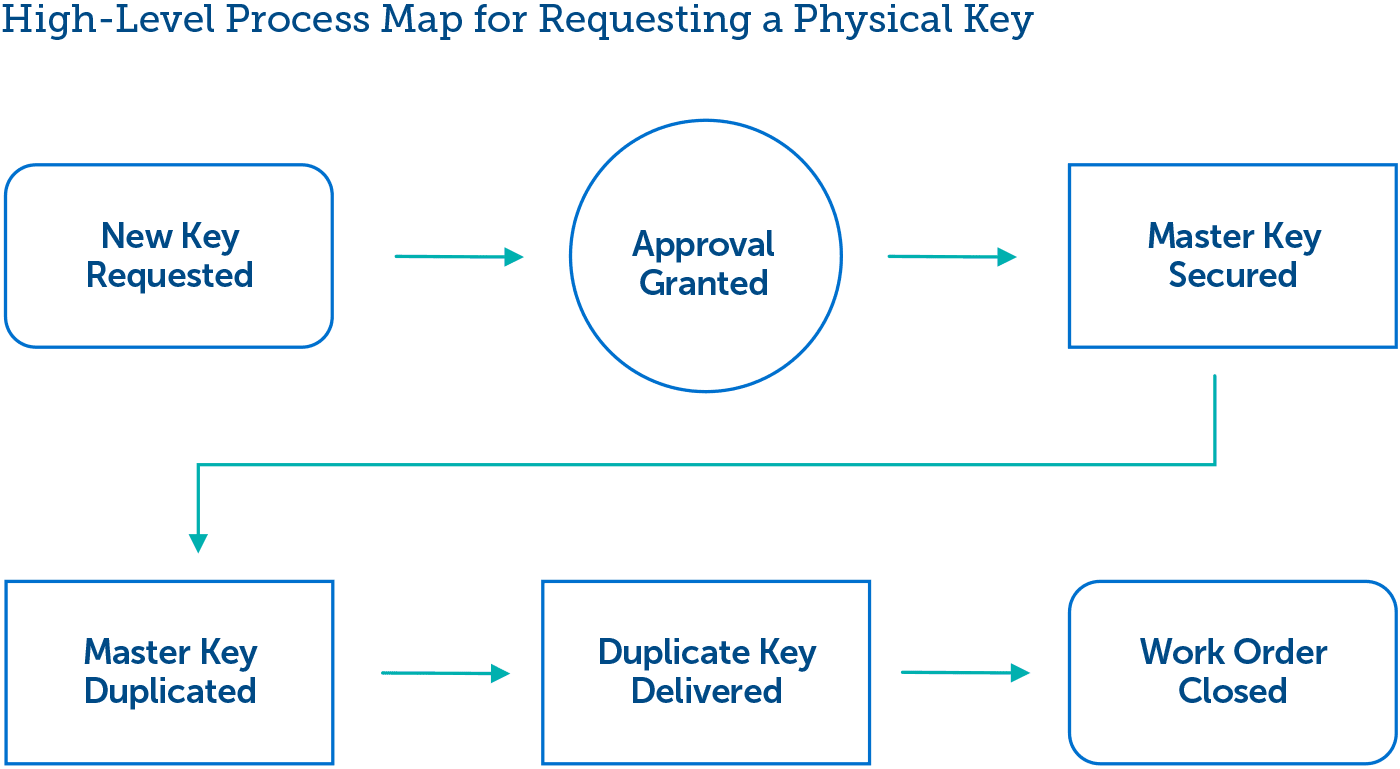

Map the current state

Process improvement teams need to understand the ins and outs of a process as it currently plays out on campus before designing a solution. Together, the team should articulate what happens, why it happens, and who is involved. Flag opportunities for improvement, but do not focus on the fix yet.

Now, make sure you understand the as-is process. Begin with a high-level map of five to seven steps, and then drill down from there to understand the value of each component of a process.

Collect current-state data

Next, select key performance indicators (KPIs) for your process improvement project. To jumpstart your efforts, review common metrics monitored in process improvement projects. Then use the data collection worksheet to create structures for collecting and monitoring the metrics to track progress.

-

Actionable tip

Establishing baseline metrics is critical for understanding where you are now and how you can improve. It’s also impossible to prove later successes without completing this step. Focus on just a handful of metrics that are important to stakeholders and are tied to the part of the process that needs the most improvement.

Sample baseline metrics

-

Lead time (total start-to-finish time)

-

Cycle time (total working time)

-

Backlog (tickets or activities not yet initiated)

-

Volume of work

-

Response/resolution time

"If you aren’t measuring, tracking, and monitoring data, then you’re not really doing the work of process reengineering.

"Vice Chancellor for Business Affairs

Public Research Institution

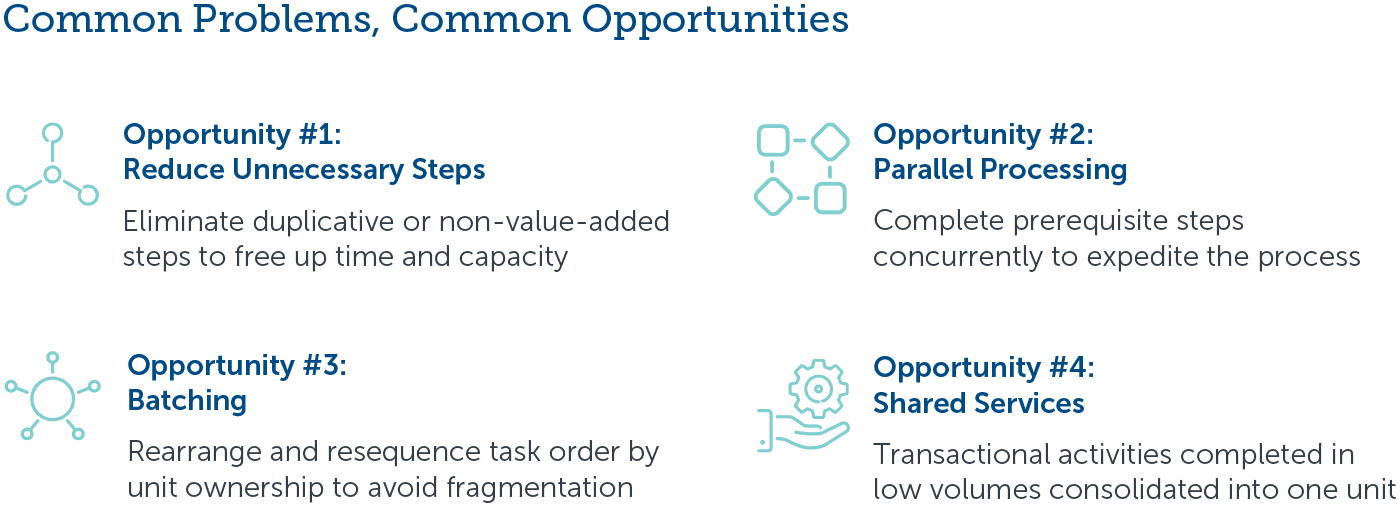

Design the future state

Now comes the fun part: determining how the revamped process should actually work. Whether designing the process from scratch, introducing automation technologies, or just reordering the workflow, look for opportunities to eliminate waste and maximize efficiency while maintaining high customer satisfaction. The metrics identified in the previous step should guide the team toward redesigning the process.

Many inefficiencies stem from a recurring set of problems. Keep an eye out for these four common improvement opportunities.

Develop a process improvement implementation plan

After designing the future state, you need a plan for how to make it a reality. Changing workflows inherently upsets the status quo, so the more thought that goes into managing this transformation, the better. The project’s executive sponsor should also be a resource during this stage to offer guidance, approve resource needs, and clear roadblocks.

Articulate a plan for how the future state will impact policy, staffing, technology, and communication—four critical change management components.

This resource requires EAB partnership access to view.

Access the roadmap

Learn how you can get access to this resource as well as hands-on support from our experts through Strategic Advisory Services.

Learn More